Mortars are used in a wide range of applications. When aesthetic appeal is a priority, AALBORG WHITE® is often included in the formulation.

AALBORG WHITE® with its high reflective index, in addition to high strength and consistent chemical composition, makes it the preferred cement for many mortar products like colour mortar, tile adhesives and grout, skim coat, self-levelling floor screed, swimming pool plasters, etc.

Bright, rich colours are achieved by combining AALBORG WHITE® with colouring pigments. Colouring is usually achieved with synthetically produced in-organic pigments, which are lime-proof, alkali-resistant, weather resistant, and non-fading.

Technique Plaster and stucco can be applied by machine spraying or by handtroweling, as single or multiple coatings and the surface texture finishing can be designed as smooth or coarse in different textures like float, dash, lace and scraped…

Sub-segment

Plaster & Stucco

Plaster and stucco made from AALBORG WHITE® not only result in strong and weather resistant facings, but create an attractive environment with room for individuality. When facings are coated with coloured plaster or stucco incorporating AALBORG WHITE® the result is unparalleled depth and intensity of colour.

Masonry Mortar

Masonry mortar is produced from instead of grey cement where sharp contrast or light coloured bricks and blocks are desired.

Tile Adhesives and Grouts

Adhesives and joint fillers can be produced from AALBORG WHITE®. In cases where thin, lightly coloured tiles or mosaics are used, it can be an advantage if the underlying adhesive is also lightly coloured. AALBORG WHITE® is the ideal binder for adhesives and joint fillers.

Self-Leveling Floor Screed

The advantage of using mortar based on AALBORG WHITE® for Self-leveling floor toppings clearly lies in the high reflection of the finished surface, and the effect that this has on brightening up a room. In addition, AALBORG WHITE® ensures optimum strength and durability.

Definition

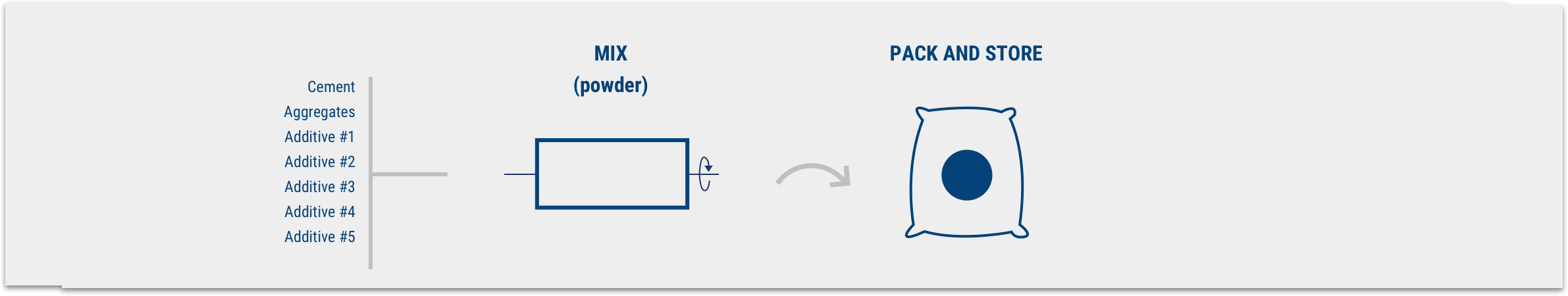

Dry powder products ready to be used when mixed with water. The products are produced in dry-mix mortar plants where cement, aggregates and different additives and admixtures are mixed dry and packed in bags. The products are palletized, stored and sold.

Voices of Customers