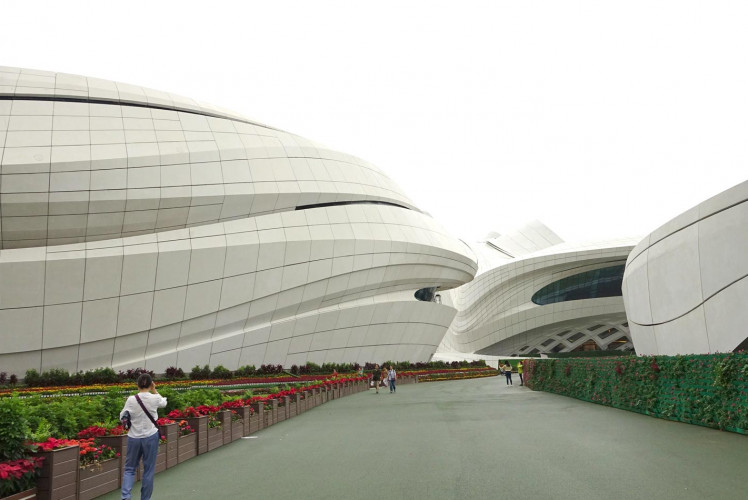

The 115,000 m2 international culture and arts center, located in the heart of Changsha City, Hunan province of China, was completed with its 53,262 m2 Glassfiber Reinforced Concrete (GRC) façade panels at the end of Aug.2017. AALBORG WHITE® was the exclusively specified White Cement product for this civic architecture, designed by Zaha Hadid Architects. To realize Zaha Hadid ‘s consistent exaggerated abstract architecture design style, more than 2,200 precast GRC panels in irregular shapes were applied to three extreme sinuous buildings. Nanjing BEILIDA New Material System Engineering, as the main GRC producer in the project, spent a total of 3 years on this masterpiece project, in which 2 years were spent only on design optimization as well as its innovative patented GRC assembling system, which is especially suitable for non- linear architectures.

AALBORG WHITE ® IN GRC APPLICATION

Grade 52.5 AALBORG WHITE ®, produced at Cementir’s plant in Anqing, Anhui of China, was the exclusively specified white cement for manufacturing GRC products for this project. This was a logical consequence of the high-quality track record of this cement from Zaha Hadid’s last project in Nanjing, China in 2014 “Olympic Youth Center”. AALBORG WHITE® is the reliable brand for stable quality in terms of stability, whiteness and mechanical performance in GRC production.

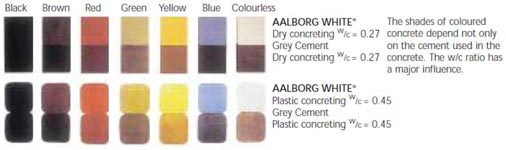

Leveraging from the very high purity and stability of Cementir ́s white cements, manufacturers of GRC pass high performance and color stability on to their end customers, in their finished

products. High purity and stable white cement is the key to all colored products - even grey cement based architectural products are often based on white cement to achieve a constant surface color.

Chemical stability of the cement plays a paramount importance on the quality of the end concrete product. Cement is globally combined with many types of chemical admixtures for almost all applications served. These admixtures have become increasingly efficient during the years and having enormous influence on the concrete industry. This has further elevated the need for skilled workforce and extended quality control systems to be implemented at the manufacturers plant. A sprayed GRC will typically have to be highly robust to maintain its integrity as it undergoes high speed mixing, “stationary” storing in the feeding tank, pumping, spraying and troweling.

The skilled workforce at BEILIDA New Material System Engineering - a GRCA Full Member of the International Glassfiber Reinforced Concrete Association (GRCA) – has fully utilized all features of Cementir ́s AALBORG WHITE® cement to realize this magnificent structure.

For more information in GRC (guidelines for specifiers, production quality testing, technical information about the product, etc.) consult www.grca.org.uk.

Location

China

Completion Year

2017

White Cement Product

Industry

Building / Commercial Structural

Application

Precast concrete / Glass fibre reinforced concrete (GRC)

Descriptions

cladding

Manufacture

Nanjing BeiLida New Material Shandong Jinguang GRC

Architects

Zaha Hadid Architects